Storage Systems

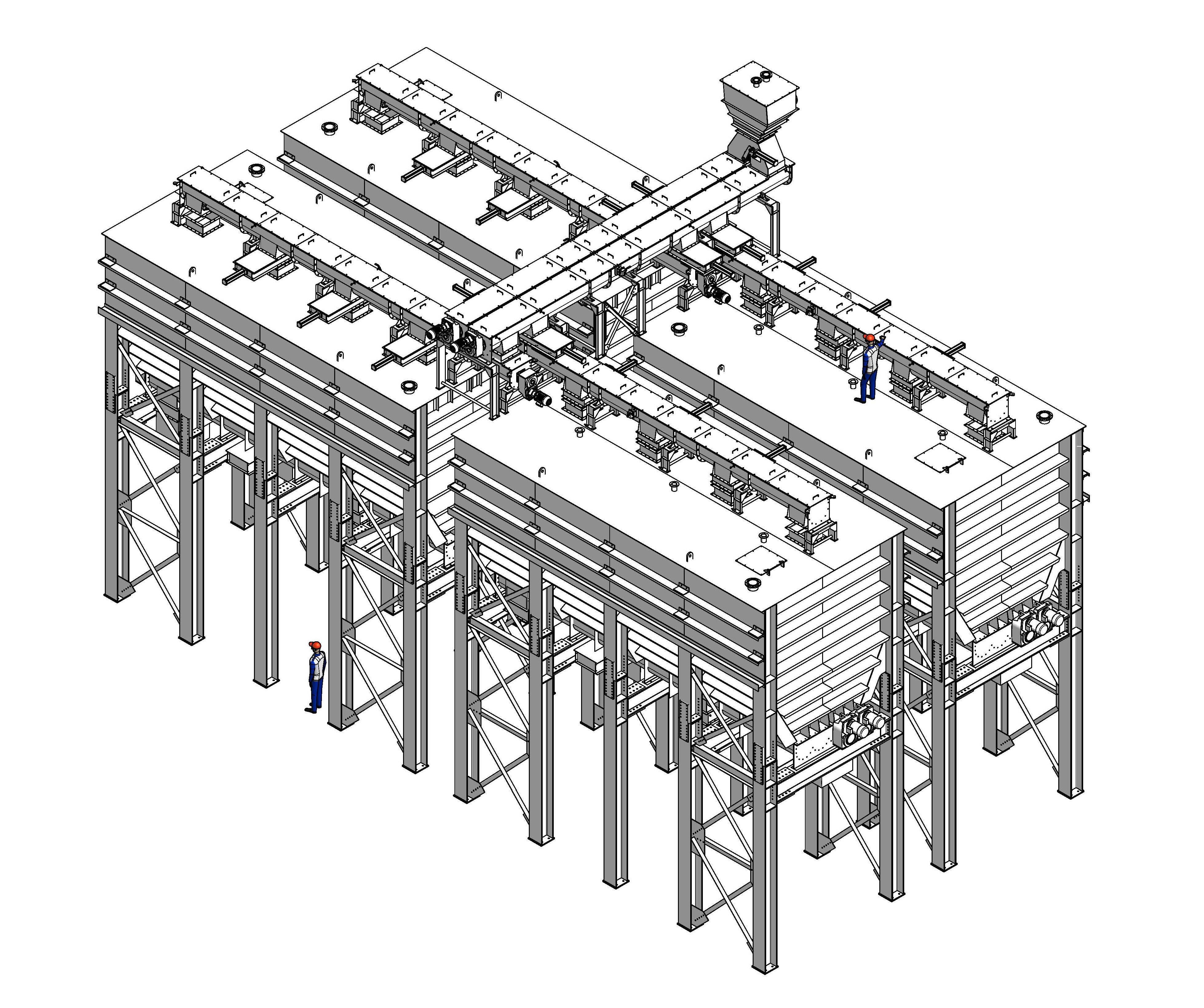

Our storage systems are designed specific to your application. They may be bolted or welded construction types or a combination of both. Our storage systems are available in AISI 304 or 316 grade stainless steel or alternately carbon steel painted or hot dipped galvanized. Storage units can be completely enclosed containers fed by conveyors or may be open-top receive containers to accept product from trucks and/or conveyors.

Custom Conveyor, A Division of Schwing Bioset, categorizes storage vessel types by the following method:

Hoppers

Hoppers are free standing square or rectangular in shape.- Hoppers vary in size from small to very large capacity.

- Elevated Storage type live bottom conveyors are utilized for truck load out or process distribution.

- Receiving type are usually below grade to receive product dumped by truck and utilize live bottoms feeding a vertical or inclined conveyor to move product to a higher elevation.

Bins

The defining feature for a bin is that they are portable in some way.- Bins are generally square or rectangular, but can be cylindrical.

- Generally have a small open top, but can be closed.

- May incorporate integral feed conveyor (i.e. Augie Dumpster*)

- Typically dumped for excavation, but live bottom conveyors optional.

Silos

Silos are cylindrical in shape.- Silos are usually large volume vessels and often have to be delivered in sections for site assembly due to shipping limitations.

- Live bottom conveyors are utilized for truck load out or process distribution.

- Dry lime utilizes volumetric or rotary feeders with a screw or pneumatic conveyors.

Contact us to inquire about our storage system options.

*Augie Dumpster

Custom Conveyor, A Division of Schwing Bioset, offers a stand-alone, self contained, self filling, and self leveling, enclosed dump-bin for wastewater screenings, grit, and sludge. It is a proven clean and odor free, automatic disposal system.

The covered load-out bin uses a standard waste container (roll-off) with our uniquely designed permanent steel top cover, internal leveling screw, and internal electrical level with multiple drop points. When the roll-off container is full, the entire dumpster is loaded on a standard roll-off dumpster truck and taken to the landfill with no odor or leakage in transit. The covered load-out dumpster design is adaptable for a single or multiple container system. Our automatic feeder conveyor systems are an available compliment to the bins.

_-_Low_Res/Custom_Conveyor_Logo_-_Final_(August_2020)_-_Low_Res_460x140.jpg)