Gates to Control Material Flow

Controlling wet product by gates and sealing it in a horizontal blade application is an engineering challenge that Custom Conveyor, A Division of Schwing Bioset, has met with over 30 years’ experience in gate design.

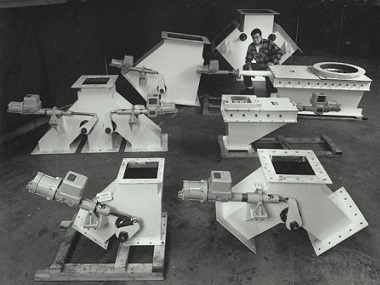

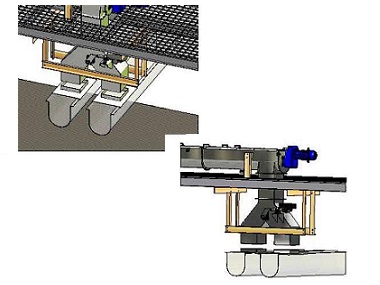

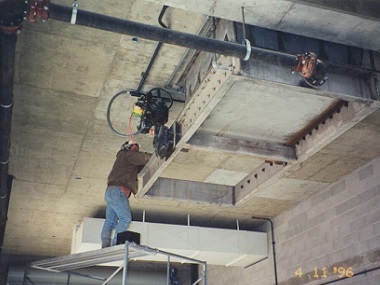

We design and manufacture gates in four basic categories. Our gates control the discharge of materials from centrifuges, hoppers, bins, silos or conveyors. The gates consist of a rigid frame mounted to the bottom of the storage, process device or conveyor. Gates may be simple slide type utilizing ultra-high density polyurethane or roller type with cam followers. Blade thickness requirements are calculated and seal selection is based years of empirical experience. Gates in low solids applications may incorporate drain rails to capture and drain minor leakage. They may be operated manually or with pneumatic, electric or hydraulic actuators.

Custom Conveyor, A Division of Schwing Bioset, can assist you in choosing the correct gate for your application or design and manufacture custom gates for your specific requirements – contact us today.

-

Diverter Gate -

Diverter Gate -

Load-out Gate -

Load-out Gate -

Load-out Gate -

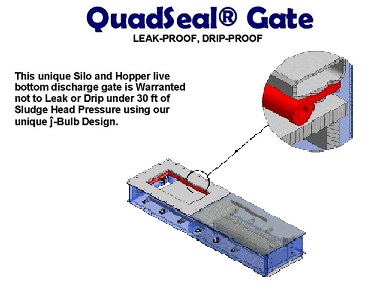

QUADSEAL Gate -

QUADSEAL Gate

QuadSeal™ Hopper Gate

Our unique QuadSeal™ gate is a heavy duty gate designed with a unique mechanical J bulb compression seal that is designed to work with high overhead pressure. This gate becomes tighter as the overhead load increases. It is typically used under sludge silos and hoppers with large volume loads.

_-_Low_Res/Custom_Conveyor_Logo_-_Final_(August_2020)_-_Low_Res_460x140.jpg)